Products

JL-1.0-600 (6.3T) Expanded Metal Machine

1: JL-1.0-600 (6.3T);Expanded metal lath making machine

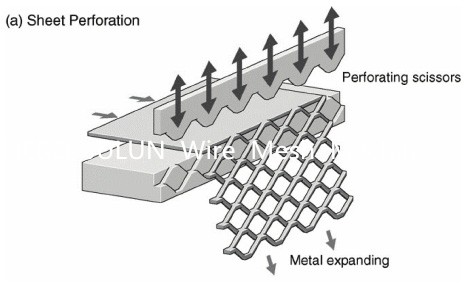

Expanded metal mesh production process:

1. Sheets or coils or metal are fed into the expanding mesh machine. A little metal can create a lot of mesh, adding value and saving resources and money.

2. Each machine is fitted with a unique "Knife", dedicated to a particular pattern. New patterns and knives can be created in-house for specific applications.

3. The machines are then programmed or manually controlled to ensure the metal is expanded to the exact specification. Rigorous quality checks are carried out to ensure product consistency throughout the expanding process

4. Using the unique shearing and streching process means very little waste is created. the metal is sheared and then streched in a single process creating the apertures and therefore expanding the metal. The mesh is then either cut into sheets or wound onto coils ready for shipping or further processing

2: The (expanded mesh machinery; expanded metal lath machine) can process cold-rolled steel, aluminum material to expanded mesh with hexagonal, diamond, half round, etc. which are used for building, hardware, machine tool, electric industrial, protective and decoration of household electrical appliances.

Material strength is under 450N/mm2, material with elongation over 25%.

Expanded process is finished by crankshaft connecting rod system, moved by can ,feed by stepping motor, the feeding distance can be easily adjusted. This machine has characteristics of structure, easy operation and steady performance.

Main technical parameters: | |

Model: JL-1.0-600 |

Typical application of expanded metal mesh: